Steel Fabrication Company Ajman

Are you looking for a Steel Fabrication Company in Ajman Dubai? JBM is one of the leading steel fabrication companies in Ajman. We have fully skilled fabrication staff who provide complete fabrication services at affordable prices. If you have any inquiry then Contact Us:

What is Steel Fabrication

Steel Fabrication is a process of cutting, assembling, and bending a metal to make custom shape. Its design and shape are based on Draftman drawing.

What We Provide in Steel fabrication?

Structural Steel Fabrication

Structural Steel Fabrication have a different structures such as angels truses, hollow section. The following tools are used chiseling and and sharing

- Leaser Cutter

- Water Jet

- Plasma Torches

Stainless Steel Fabricators

In stainless steel there are are types Carbon steel(0.4), ferritic steel(0.4), and austenitic steel (0.2)

Metal Fabrication

In stainless steel there are are types Carbon steel(0.4), ferritic steel(0.4), and austenitic steel (0.2)

What we do in Steel Fabrication Workshop

Our Steel Fabrication work starts from the cutting of the raw material (Note: Saw, Punch press, and laser cutter are mostly used for cutting). The second step is Punching, we make a hole and other formed characteristics.

Here are some Steel fabrication treatments that help improve steel and aluminum fabrication work life.

- Heat Treatment increases the strength by modifying the microstructure of steel.

- Coating is applied onto the surface of steel to improve quality, appearance, and durability. It can include powder coating and painting which also give a slight texture to it.

- The galvanizing process prevents steel from rusting by covering it with a layer of zinc.

- Deburring removes unwanted pieces or raised edges from steel that are caused by cutting, shearing, etc.

Manufacturing Process of Steel Fabrication

The Steel fabrication is separated by two manufacturing processes, the Primary Metal fabrication is used to create simple and semi-finished metal products like plates, sheets, tubes and bars, whereas Secondary fabrication focus on taking semi-finished metal products from primary fabrications and reshaping it according to customer requirements. These secondary products include steel trusses, storage tanks, automotive chassis, and metal enclosures.

Pre Process of Steel Fabrication:

It involves planning the final product before working to prevent any errors.

Design and Drafting in steel fabrication is the preliminary stage which involves

Analyzing the structural strength, deflection, surface hardness, etc. Also checking type and quantity of raw material. Avoiding any errors by creating construction drawings which is now usually done by software like AutoCAD.

Workpiece Preparation like waterjet cleaning, scraping or brushing are done to remove any surface contaminant that can affect Steel fabrication process.

Marking is included in preparation process to lay off measurements from the design with the help of metal scribers, pencils etc.

Raw Materials for Steel Fabrication:

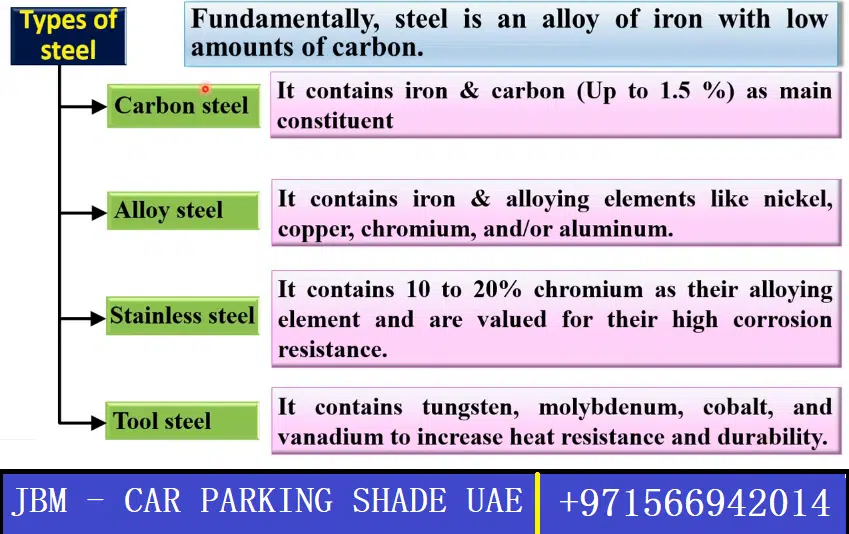

It is an iron base metal alloyed by carbon. Mostly stainless steel is used for its variety of uses consisting various grades suitable for different applications.

- Castings are produced from metal ingots. They are shaped according to the final product.

- Blooms are semi-finished metal stocks produced after first breakdown of metal ingots. They have a 6×6 inch or greater square cross-section.

- Slabs have a thickness around 8 inches or greater. They are produced from rolling metal ingots and have a rectangular cross-section.

- Billets have a 2×2 to 5×5 inches square cross-section. They are actually blooms which goes through more rolling, forging or extrusion.

- Plates, Sheets, and Strips are produced from blooms and slabs. Plates have a thickness greater than 0.25 inch whereas sheets and plates are thinner than plates.

- Bars are produced from rolling billets into 0.5 to 2 inches square, round or rectangular cross-sections.

- Rods have 0.2 to 0.5 inch cross-section which made them easily bent.

- Beams, Channels, Angles, and Rails are formed from blooms by progressive rolling which is the reason for their irregular cross-sections.

- Welded Tubes are made by rolling and welding a slab or plate whereas seamless tubes and pipes are made by a round bar pierced using a rotating cone.

- Wires are formed by a process called Drawing which is done at room temperature this process, a metal piece, typically a rod, is pulled from a die.

What is Cutting in Steel Fabrication:

Cutting is used to clean product from unwanted material in steel fabrication. There are several methods for it.

Traditional Cutting:

- Shearing uses two tools passing each other closely and cutting the steel between them. It comes with different tools like blanking, piercing, Parting, Notching, Trimming, etc.

- Sawing uses traditional or mechanical saw which cut by rotating or reciprocating.

Thermal Cutting:

- Laser Cutting is a method which uses intense lasers to cut through steel.

Mechanical Cutting:

- Water Jet Cutting uses high pressure of water mixed with abrasive material to cut through steel by eroding the surface.

What is Bending Steel Fabrication:

In steel fabrication bending works by supporting the material at two points or more and applying pressure. Sheet, plates and rods are commonly bent into V-shaped, U-shaped by this method.

- Air Bending uses two points to support steel and bends it by applying pressure on the upper side but not contacting its bottom side.

- Bottom Bending also use two points like air bending but it applies pressure until steel contacts its bottom side.

- Coining requires higher force than air or bottom bending which cause steel to completely change its shape which makes coining highly accurate.

- Roll Bending consist of one moving upper roll and two stationary lower rolls. Steel pass into these rolls and bends according to radius given.

What is Assembly and Joining Steel Fabrication:

This process in steel fabrication includes joining all parts to analyze whether they fit properly. Initially non-permanent joints are done to check the structure. After surety permanent joints are done mostly by welding or by bolts.

- Welding involves joining steel by heating and melting it. The filler metal and molten steel form a weld pool after cooling and become solid joint. Welding has various types like shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW/TIG), etc.

- Soldering and Brazing does not melt the steel but join it by melting a filler metal into the joint. For the filler Brazing uses brass while Soldering uses silver and tin-lead alloys.

- Bolting, Screwing and Riveting are semi-permanent joints that can be undone without damaging. It requires holes to insert bolts and has to be checked regularly for any loosen bolts. Whereas Riveting is mostly used in steel sheets.

About Us

J.B.M Car Parking Shades was established in 2018 We are a Manufacturer and Supplier of Customized Steel Fabrication In UAE. Our Company also provides all types of shed and Pergola Fixing and Installation Services in Dubai, Sharjah, Ajman, Ras al Khaimah, and Abu Dhabi.

About Us

- Industrial Area Ajman UAE

- info@j-b-m-car-parkingshades.com

- 0505121672

- 0566942014